The production of hydrogen and other sustainable fuels like methanol is essential for decarbonizing the economy and advancing the transition towards a more sustainable energy model. However, to achieve this, it’s necessary to progress in the implementation of these technologies, including production, storage, and transportation.

Cocusing on production, as discussed in others AtlantHy Academy articles, there are significant inefficiencies in current projects, necessitating the dissipation of large amounts of low-temperature heat. Thus, cooling systems become critically important in such facilities, even though they are sometimes considered secondary.

Previous articles have addressed water consumption in hydrogen and methanol projects, emphasizing efficient water management in cooling systems. This time, we delve deeper into these technologies, exploring the different types that may be required based on specific installation characteristics and their role in the technical and economic viability of projects.

Cooling Systems

Cooling is required in these production processes, just as it is in other industries like automotive and food. Traditionally, its importance has been overlooked since it’s neither a raw material nor a final product. However, inefficiency in cooling can lead to significant process cost increases and is closely related to environmental impact due to higher energy and/or water consumption, potentially jeopardizing projects.

The cooling demand of installations varies depending on the selected electrolysis technology, as it partly depends on efficiency and associated energy losses (Joule effect), being crucial to ensure system stability. Therefore, cooling systems are required during operation to prevent potential equipment degradation due to overheating.

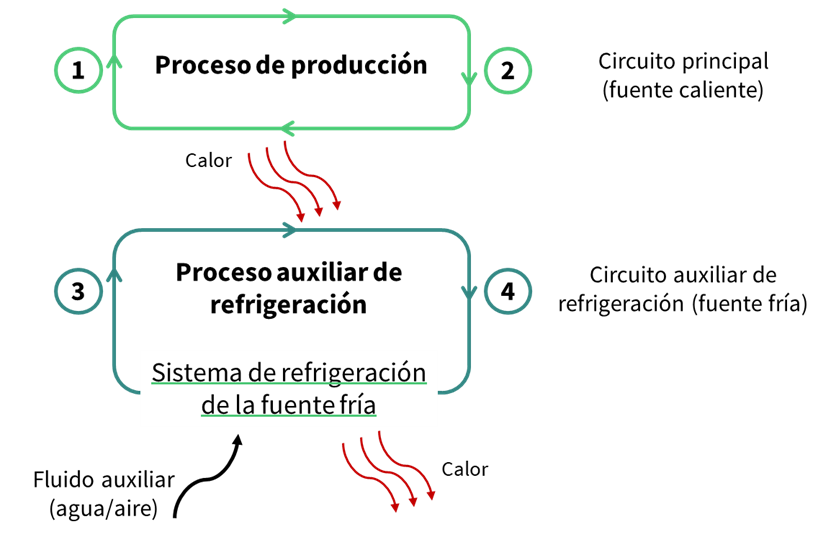

The cooling process operates on heat exchange between the hot source of the process (main circuit), such as an electrolyzer, and a cold source that absorbs the excess generated heat (auxiliary cooling circuit). This process is key to maintaining thermal equilibrium, ensuring operation within the required appropriate and balanced ranges.

Simultaneously, cooling systems cool the cold source, which has absorbed heat from the process and has been heated, allowing the coolant to regain its cooling capacity and be reused in a continuous cycle.

In this final stage, the technologies mentioned below come into play, typically using water or air as the primary medium to reduce the coolant’s temperature again.

Schematically, this is summarized in Illustration 1, as both processes integrate to achieve plant cooling.

Illustration 1. Cooling in production processes.

Cooling Methods Used

Selecting an appropriate cooling system depends on various factors, including the plant’s environmental conditions and specific cooling requirements, both in terms of target temperature and the amount of thermal energy to be dissipated. Additionally, it’s essential to consider resource availability, such as water or air, and local regulations that may influence system choice.

All these factors should be considered from the electrolyzer selection stage. For instance, if water cooling isn’t feasible at a particular location, choosing an electrolyzer requiring higher temperature cooling might be advisable, allowing the use of air cooling systems and operation even during summer months when air coolers struggle to dissipate heat.

Each cooling system presents different performance levels, resource consumption, and space requirements. Generally, for cold sources, heat is dissipated until temperatures between approximately 25 and 45 ºC are reached.

Two main types of cooling are commonly used in such projects, based on using ambient air or water. These will be explored in detail below, addressing questions like: What are the advantages and disadvantages of using water versus air? What are the most restrictive criteria for cooling systems? Which industrial cooling requires the most investment?

Water cooling

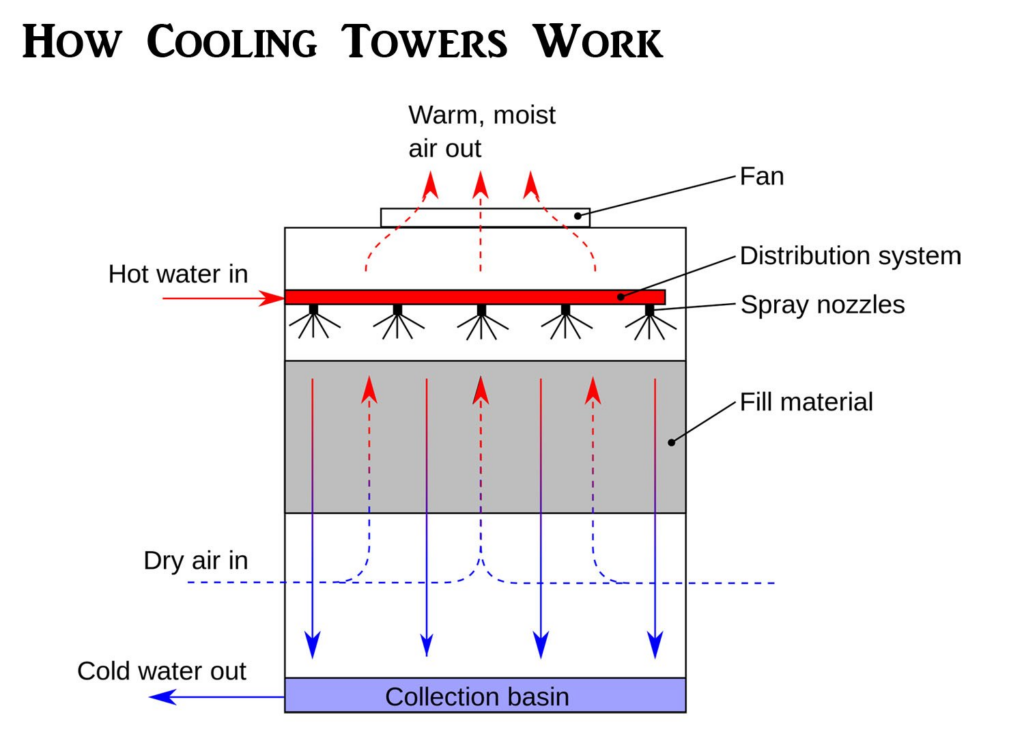

When we talk about water-based cooling systems, the technology used in this case is cooling towers, which are designed to cool a fluid stream through the partial evaporation of water.

Water cooling systems utilize cooling towers to cool a stream through partial water vaporization. This technology leverages both the water’s temperature and the energy consumed during partial water evaporation, which is then carried into the atmosphere by the system’s air. This principle combines sensible and latent heat transfer, maximizing thermal dissipation efficiency. Hot water is typically sprayed inside the tower, coming into contact with cooler air, reducing its temperature before recirculation.

Depending on how air is supplied to the system, cooling towers can be broadly classified into two types: natural draft and forced draft. Forced draft towers use fans to increase air velocity, significantly reducing size and investment costs, making them the most commonly used option at an industrial scale. They also allow easier temperature control based on the air flow rate.

Illustration 2. Natural draft cooling tower.

Additionally, classification can be based on operational characteristics:

- Open circuit towers allow hot water to be in direct contact with air, promoting evaporation and achieving high heat loss efficiency.

- Closed circuit towers enable hot water or another coolant to circulate through a coil, preventing direct contact with air. This reduces water loss through evaporation and contamination risk. The cooling system’s water is sprayed separately from the cold source.

Illustration 3. Forced draft cooling tower. Source: (BALTIMORE AIRCOIL COMPANY, 2024)

Cooling towers are designed with several essential components to ensure efficient operation:

- Fill media increase the contact area between water and air, significantly improving heat transfer.

- Water distributors evenly disperse hot water over the fill media, maximizing efficiency.

- The collection basin gathers cooled water, preparing it for recirculation.

- Fans facilitate the necessary air flow for evaporation.

- Drift eliminators minimize water loss in the form of droplets carried by the air.

Moreover, these technologies must comply with current health regulations to prevent the proliferation and spread of Legionella bacteria by controlling water quality. Conditions should not favor bacterial growth, and appropriate biocides and purification systems must be applied.

Illustration 4. Cooling tower operation diagram

The water quality typically needs to meet potable network water standards, although there is some flexibility depending on the type of fill material used in these systems. The chosen fill should minimize fouling, corrosion, and organic growth. It’s important to note that using a fill that allows for lower water quality results in reduced process efficiency and, consequently, an increased required flow rate.

Air cooling

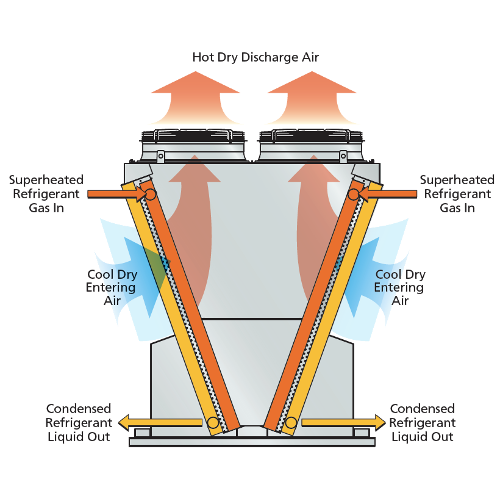

Air cooling technology, known as “dry coolers,” relies solely on ambient air and temperature to remove heat from the system. The main advantage of this approach is the elimination of water usage; however, it requires a larger contact area to dissipate substantial amounts of energy.

Since water isn’t used in the process, a higher volume of air is needed to cool the same amount of energy from the primary process. Heat transfer in these cases depends exclusively on the sensible heat difference with the air.

At this point, the ambient temperature where the plant is located becomes more significant, as the minimum achievable temperature with the cold source is more limited compared to systems that also use water for cooling. This is based on the differences between dry air temperature and wet bulb temperature (related to ambient humidity).

Illustration 5. Operation of air coolers

Specifically, these units can have various configurations, differentiated by the direction and point of air flow entry, using fans to modulate air speed to achieve the desired temperature. In the case of Illustration 6, air enters the unit through the dark panels on the sides. The hot water from the auxiliary process contacts coils placed inside.

Illustration 6. Dry cooling technology (“dry coolers”). Source: (TORRAVAL, 2024)

Mixed cooling

Finally, mixed cooling is an intermediate solution similar in form to “dry coolers,” but it does involve the use of water in the equipment. The main advantage of this technology, known as “adiabatic coolers”, is that it allows the equipment to operate solely with air as long as the local temperature permits; when this isn’t possible, it switches to water-based cooling. This hybrid solution enables a broader range of cooling temperatures, reducing the water consumption required for operating a cooling tower.

This approach significantly optimizes water consumption throughout the year, which is often a critical parameter in Spain, as various regions frequently face or are at risk of water stress.

Technology selection

When choosing a cooling technology, it’s essential to consider the specific circumstances of the project under evaluation. To select the most efficient and safe cooling system for a hydrogen plant, one must assess the advantages offered by different cooling systems. Graphically, we’ve summarized this in Illustration 7.

Illustration 7. Key parameters for selecting a cooling system.

Water Consumption: A Crucial Issue

Water consumption is one of the most notable differences among these systems. In the case of cooling towers, this consumption is considerably high. However, this high water demand translates into efficient cooling, making them ideal for large-scale applications, such as industrial plants, where this isn’t a constraint.

On the other hand, adiabatic systems stand out for their low water consumption. They only use water during specific times, like extremely hot days, making them much more sustainable. They can operate at similar temperatures, consuming between 80% and 95% less water than cooling towers. However, the acceptable water quality for this system is also more stringent.

Regarding water consumption, the clear winner is dry cooling using “dry coolers,” although in certain climates, like parts of Spain, they might not be sufficient to achieve the low temperatures needed during summer months.

It’s always necessary to evaluate temperatures and humidity in the environment to determine the most suitable system. At AtlantHy, we’ve developed very interesting designs by considering these variables.

Electricity Consumption

Considering the mentioned characteristics of the different systems, dry cooling stands out for its high energy consumption. This is due to the greater power required and the higher number of units needed to achieve similar performance. In this regard, adiabatic towers offer a significant advantage: although they have high water consumption, they compensate with considerably lower electricity usage. Conversely, installing dry cooling systems, like “dry coolers,” leads to a notable increase in energy costs due to their continuous operation.

Equipment Size and Installation Flexibility

The space required for installing cooling towers is significantly less compared to what’s needed to dissipate the same amount of heat using systems like “dry coolers” or “adiabatic coolers.” This makes towers one of the most attractive options, especially when available space is limited, as this constraint could prevent the installation of the necessary capacity with other systems. However, “dry coolers” and “adiabatic coolers” have the advantage of being installable on elevated structures that ensure adequate airflow between units. Therefore, these more compact solutions can also be used in cases where space is a challenge, installing them, for example, on rooftops with structures designed to support their weight.

Initial Investment

The cost of “adiabatic coolers” is usually higher than that of cooling towers due to their advanced design and the technology involved in their operation.

Although this initial investment is higher, it can be justified in projects where water availability is limited or where installation conditions demand more flexible and technologically advanced solutions.

Conclusión

Choosing between different cooling systems depends on various factors, such as water consumption and quality, available space, and specific cooling needs. Towers offer greater capacity and efficiency in large installations but with high water consumption. In contrast, adiabatic systems are compact, consume less water, and are ideal for regions with water limitations, although they require more space. Similarly, dry cooling would be the option that doesn’t consume water but might not be sufficient in certain regions.

In summary, understanding the differences between these systems is crucial to making the best decision based on the conditions and priorities of each project, as the choice varies depending on

If you’d like to learn more about cooling systems in hydrogen projects, check out Episode 79 of El Podcast del Hidrógeno.

At AtlantHy, we are deeply involved in the development of various projects where analyzing this key factor helps improve and ensure the feasibility and development studies. If you have any questions or need further information on this topic, don’t hesitate to contact us. Shall we talk?

References

BALTIMORE AIRCOIL COMPANY. (2024). Torres de enfriamiento abiertas. Obtenido de https://www.baltimoreaircoil.eu/es/productos/torres-de-enfriamiento-abiertas

TORRAVAL. (2024). Dry Coolers. Obtenido de https://www.torraval.com/dry-coolers-2/