At AtlantHy we continue to explore the future of energy and the technologies that will drive the transition towards a more sustainable model. In our previous article , nwe delved into the potential of offshore hydrogen production a technology poised to revolutionize the decarbonization of the global energy system. We examined how generating hydrogen at sea can harness renewable energy sources, alleviate grid congestion, and facilitate global energy transport. However, we also discussed the technical and economic challenges that must be overcome for this technology to become a viable and competitive option.

What is the current status of offshore hydrogen project development?

Offshore hydrogen has evolved from a theoretical concept to a strategic component of the global energy transition. Nevertheless, its commercial deployment remains in the early stages, limited to pilot plants and feasibility studies. Current objectives focus on achieving commercial maturity between 2030 and 2050, with projects aimed at demonstrating the real-world viability of proposed solutions.

In a geopolitical context marked by volatile energy markets, Europe has intensified its focus on endogenous resources as a key element of energy autonomy. The commitment to hydrogen is evident, as we’ve discussed in other AtlantHy Academy articles.

Consequently, Europe is witnessing significant growth in this technology, bolstered by the geographical advantages of the North Sea and the Baltic Sea. Both seas, characterized by relatively shallow depths (up to 60 meters in many areas), offer optimal conditions for installing wind platforms. The shallower waters simplify construction and anchoring of structures, reducing costs and implementation times.

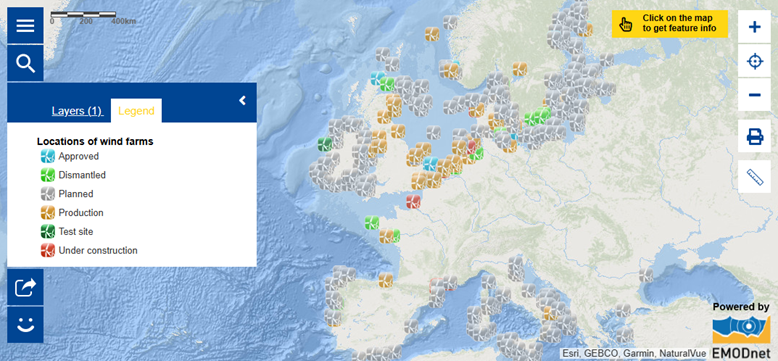

The offshore wind industry plays a fundamental role in the viability of offshore hydrogen. As illustrated in Figure 1, the expansion of wind farms in the North Sea and the Baltic Sea clearly indicates where the first offshore hydrogen production projects will emerge in the coming years.

Figure 1: Location of Offshore Wind Farms in Europe. (EMODnet, 2021)

Europe pioneered offshore wind development from its early stages. A prime example is the Vindeby wind farm in Denmark, considered the world’s first offshore wind farm. Inaugurated in 1991, it featured 11 turbines with a capacity of 5 MW. (Orsted, n.d.)

Now, history is repeating itself, but with renewable hydrogen taking center stage. The same waters that propelled offshore wind are now giving rise to the first projects combining both technologies.

After identifying potential sites for offshore hydrogen projects, the next critical question arises: How is an offshore hydrogen plant designed? What schemes exist? It’s not just about generating hydrogen but doing so as efficiently as possible, maximizing the use of surrounding structures and the energy produced by the wind farm.

Over the years, the industry has developed various approaches to optimize the available offshore elements. Some solutions aim to reduce costs and simplify infrastructure, while others focus on connecting to the onshore electrical grid. But which option holds the most promise?

Currently, there are three main approaches to designing offshore hydrogen plants that utilize energy from offshore wind farms:

Distributed Electrolyzers on Turbine Platforms

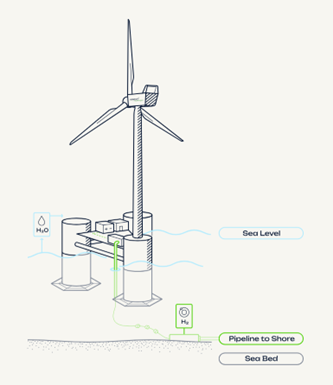

One of the initial considerations in designing an offshore hydrogen plant is the placement of electrolyzers. A clear option is integrating them directly into the turbine structures. This approach eliminates the need for submarine electrical cabling, thereby reducing costs. This strategy is exemplified by the Dolphyn project, which proposes housing PEM electrolyzers on the wind turbine platform.

Once hydrogen is generated, the next challenge is transportation to shore. Several options exist: storing it within the turbine structure for later transport by ships or, as in the case of the Dolphyn project, using the most direct method submarine pipelines. This system delivers hydrogen to the coast, where it can be stored or distributed according to market needs.

Figure 2: Illustrative Graphic of the Dolphyn Commercial Project. (Dolphyn Hydrogen, 2024)

Looking ahead, the project’s goals are ambitious. With support from the UK government, they aim to develop a 10 MW demonstration plant before 2030 as a first step toward commercializing the technology. This prototype will serve as a foundation for larger projects, with plans to build plants ranging from 100 to 300 MW in strategic locations like the North Sea or the Celtic Sea.

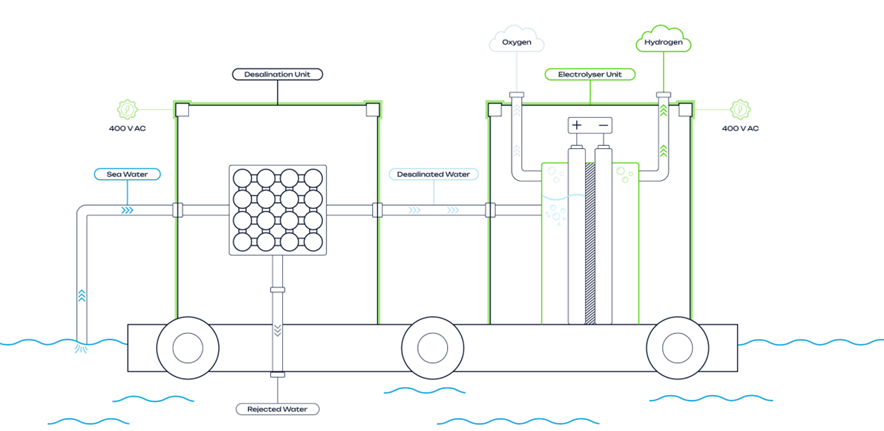

Before reaching that point, it’s essential to validate the concept under real conditions. Therefore, the Dolphyn project team has initiated offshore trials with a small experimental platform. This pilot is designed to assess the performance of desalination systems and PEM electrolysis in a marine environment, evaluating their ability to operate stably with variable renewable energy. Over a month, key factors such as energy consumption, hydrogen quality, and equipment response to changes in power supply were analyzed, simulating operation with an actual wind turbine.

Figure 3: Illustrative Graphic of the Dolphyn Project Pilot. (Dolphyn Project, 2024)

Centralized Plants with Electrolyzers on a Single Platform

Another solution involves consolidating electrolyzers on a single platform, centralizing hydrogen production and connecting it directly to an offshore wind farm. An example of this strategy is the PosHYdon project, developed in the Netherlands by Neptune Energy. The project utilizes a gas platform in the North Sea, integrating three energy sources on one platform: gas, hydrogen, and wind energy.

Electricity used on the platform comes from a nearby wind farm and powers a 1 MW electrolyzer, producing approximately 400 kg of hydrogen daily. To obtain purified water, the electrolyzer’s balance of plant includes a desalination unit.

A significant advantage of this design is the use of existing gas pipelines to transport hydrogen to shore, substantially reducing infrastructure costs and accelerating project viability. Additionally, unlike other projects, PosHYdon has strong backing, with €3.6 million in funding from the Dutch government and support from key companies in the hydrogen value chain, such as NEL, Emerson, and Gasunie. Its primary goal is to assess the practical feasibility of integrating offshore hydrogen production into existing energy infrastructures and analyze the impact of marine conditions on electrolyzer performance.

Figure 4: Q13a-A Platform

Onshore Production Using Offshore Wind Energy

This approach leverages the proximity of offshore wind farms to transmit electricity to shore and produce hydrogen on land. This creates a hybrid system where energy generated at sea is transmitted via submarine cables and, once on land, is used in the most cost-effective manner at any given time.

How Does Onshore Hydrogen Production from Offshore Wind Work?

When electricity prices are high, the energy is sold directly to the market. Conversely, when prices drop, it’s used to produce green hydrogen through electrolysis. This strategy maximizes revenue and improves system efficiency, adapting to real-time energy supply and demand. As we know, this is currently less profitable given 2025 cost structures, but it’s important to remember that these projects aim to define new energy systems, considering significant cost reductions in technologies as we’ve already observed.

An example of this model is Bantry Bay, located on Whiddy Island, Ireland. The project aims to harness 3.2 GW of renewable energy to produce green hydrogen and ammonia, contributing to a reduction of 2.4 million tons of CO₂ annually. Its strategic location facilitates integration with existing infrastructures previously dedicated to the oil industry, reducing costs and accelerating implementation. The first phase involves constructing a 2.7 GW hydrogen plant, while a second phase includes installing a 500 MW ammonia plant that will use hydrogen produced in the first stage. The project is expected to be operational by 2028.

Conclusion

Offshore hydrogen is currently at a pivotal stage of development, with multiple approaches under study to identify the most effective production and distribution strategies. The projects we’ve analyzed show that there is no one-size-fits-all solution.

As technologies mature and operational experience grows, we are likely to see a hybridization of these approaches, tailoring renewable hydrogen production methods to each unique context. With the support of institutional initiatives and the continuous progress of offshore wind, offshore hydrogen production has the potential to become a key solution in decarbonizing the global energy system.

At AtlantHy, we are closely following this evolution and actively working on the development of innovative projects in the sector, such as H2FLOAT, a research and development initiative aimed at optimizing hydrogen production, storage, and transport on offshore wind platforms. The project leverages advanced technologies such as solid oxide electrolysis (SOEL) and liquid organic hydrogen carriers (LOHCs).

This initiative, developed in collaboration with Hidritec Water Systems, Kerionics, and BlueNewables, has been recognized by IDAE as one of the most promising hydrogen innovation projects, receiving a grant of approximately €3 million. It reflects our commitment to innovation and decarbonization. If you’d like to learn more about H2FLOAT and its impact on the future of offshore hydrogen, visit our website for full details.

If you’d like to explore this topic further, don’t hesitate to contact us. We’d be happy to answer your questions and help develop your project. We’ll also continue to analyze the latest innovations in technology and infrastructure to keep you up to date on the future of this industry.

References

DEME Group. (2024). HYPORT®: green hydrogen plant in Ostend. Obtenido de https://www.deme-group.com/news/hyportr-green-hydrogen-plant-ostend

Dolphyn hydrogen. (2024). Obtenido de https://www.dolphynhydrogen.com/our-dolphyn-process

Dolphyn Project. (2024). Obtenido de https://www.dolphynhydrogen.com

EMODnet. (2021). Map of the Week – Locations of wind farms.

Hydrogen Island. (2024). Hydrogen Island. Obtenido de https://hydrogenisland.dk/en

Keogh, J. (2020). Whiddy terminal is helping to store global oil reserves. The Southern Star.

McCullough, E. (2020). Ostend wants to build largest green hydrogen plant in the Benelux by 2025. The Brussels Times.

Orsted. (s.f.). 1991-2001 The first offshore wind farms. Obtenido de https://orsted.com/en/what-we-do/insights/white-papers/making-green-energy-affordable/1991-to-2001-the-first-offshore-wind-farms

O’Sullivan, K. (06 de julio de 2021). Bantry Bay green energy facility to be one of largest of type in world. The Irish Times. Obtenido de https://www.irishtimes.com/business/energy-and-resources/bantry-bay-green-energy-facility-to-be-one-of-largest-of-type-in-world-1.4613055

RWE. (2024). Hydrogen production in the North Sea