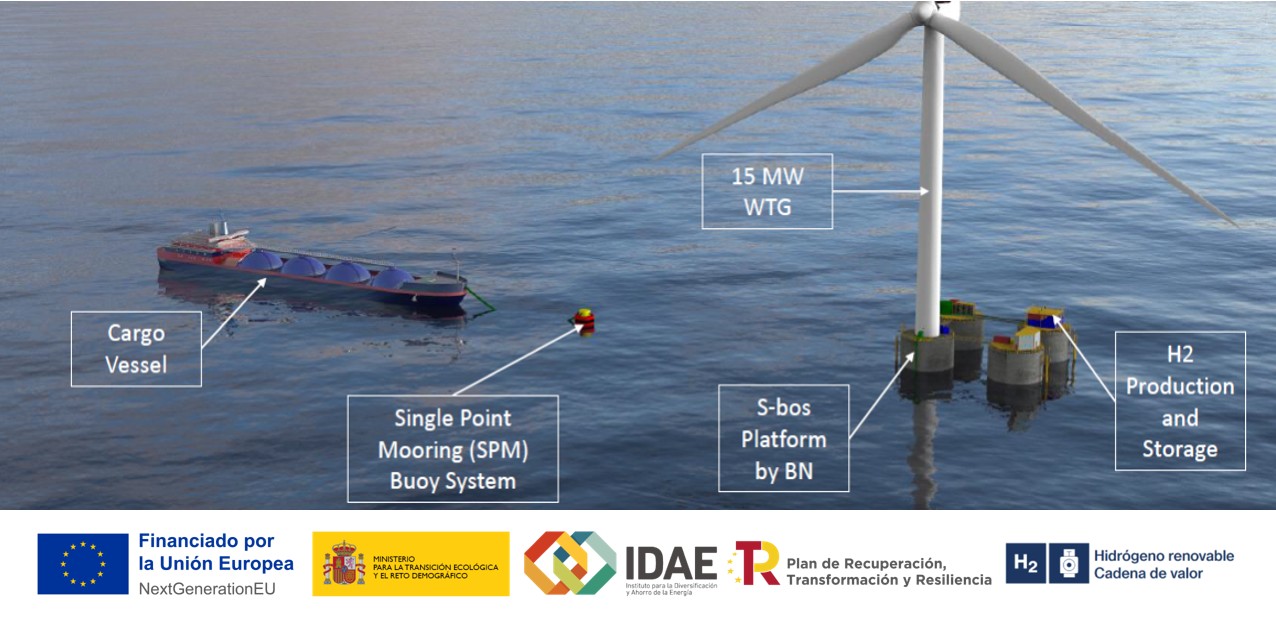

The H2FLOAT Project is an industrial research initiative that seeks to demonstrate the feasibility of producing and storing hydrogen efficiently on offshore wind platforms. The project focuses on the development of key components that enable the generation of hydrogen using solid oxide electrolysis technology (SOEL) and its subsequent storage and transport using liquid organic carriers.

H2float is an integrated solution for the generation, storage, and transport of renewable hydrogen from offshore locations to points of consumption.

H2float is the result of the common vision of four innovative companies: ATLANTHY, HIDRITEC WATER SYSTEMS, KERIONICS and BLUENEWABLES that have the clear intention to help slow down global warming, prevent the frequent occurrence of catastrophic natural phenomena, as well as to control the rise in sea levels or the risks affecting biodiversity and prevent the global temperature of the planet from rising no more than 1.5°C above pre-industrial levels.

The project aims to highlight the role of hydrogen as a vector capable of storing energy and transporting it over long distances, enabling the integration of wind resources—particularly those in remote locations—into energy systems. Meeting the targets and becoming carbon neutral by 2050 will require the installation of more than 3,000 GW of electrolysers, compared to an almost negligible value today. These electrolysers will demand TWhs of energy year after year, adding to the already growing electricity demand. However, the energy required to power the electrolysers must not compete with the energy dedicated to other electrifiable uses or congest existing power grids. For this reason, all hydrogen production projects will need to have associated renewable power plants capable of meeting their energy demands.

Offshore wind energy and its link to hydrogen has received more intensive research in recent years. The reason is simple: the best wind resources are located in areas of the ocean far from civilisation, where laying electrical transmission lines to harness that energy is completely unfeasible. However, with hydrogen, this becomes possible, as it is storable and transportable. Even so, the idea of installing a hydrogen production and conditioning system for transport from offshore wind platforms is still a very immature concept and presents major challenges. These include the need for large storage volumes, the low efficiency of the most mature electrolysis systems (which results in energy losses that affect the system’s economy and efficiency), and the high costs associated with compressing and liquefying hydrogen or producing ammonia for subsequent transport. H2FLOAT will demonstrate an alternative through a high-efficiency model for hydrogen production, storage, and transport, offering substantial storage capacity and easy delivery of hydrogen to the locations where it is needed.

To make this project a reality, funding has been requested under the Incentive Programme for the Innovative and Knowledge-Based Hydrogen Value Chain, part of the Recovery, Transformation and Resilience Plan. This initiative, financed by the NextGenerationEU funds and managed by the Institute for the Diversification and Saving of Energy (IDAE), provides crucial support for the development of strategic technologies in the hydrogen sector. The total grant awarded to the project amounts to €2,913,404.14, enabling progress in innovative solutions for the production, storage, and transport of renewable hydrogen in offshore environments. |