In the race to decarbonize industry, green hydrogen is emerging as one of the most promising solutions. However, its economic viability depends on multiple technical and energy-related factors that directly influence the Levelized Cost of Hydrogen (LCOH)—the key metric that defines the real cost of hydrogen produced over the entire lifetime of a plant.

How does this cost vary depending on location, electricity prices, or plant design? In this article, we break down the most critical variables influencing the LCOH and demonstrate, through our own techno-economic model, how to optimize each aspect to increase the profitability of green hydrogen projects via electrolysis.

What is the weight of OPEX in the LCOH?

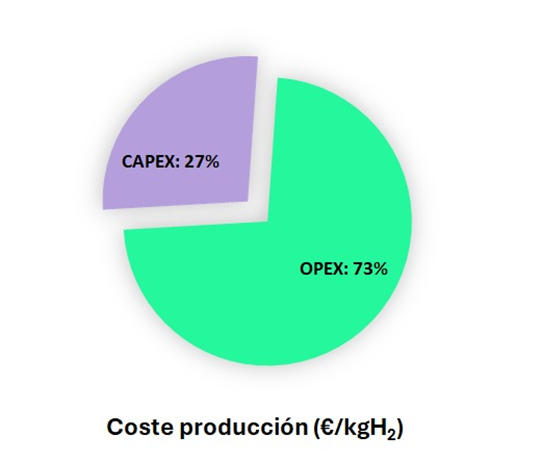

In current electrolysis systems, operational expenditures (OPEX)—with electricity consumption as the main component—account for between 60% and 75% of the Levelized Cost of Hydrogen (LCOH).

Illustration 1. Distribution of CAPEX and OPEX impact on LCOH

This proportion makes the price of electricity the most decisive factor for economic viability, far more so than the initial investment (CAPEX). Therefore, securing a competitive and stable electricity supply is the foundation for achieving economically viable green hydrogen.

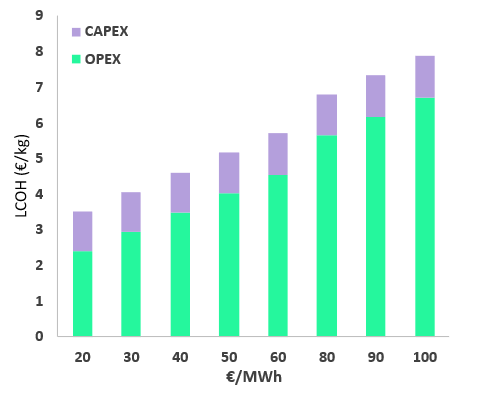

Illustration 2. Impact of electricity cost on LCOH

In our techno-economic model, we analyze how the LCOH changes when only the electricity price is modified, keeping all other parameters constant. The result is conclusive: a 10 €/MWh increase in electricity price raises the LCOH by approximately 0.5 €/kgH₂.

In other words, doubling the electricity price—for example, from 40 to 80 €/MWh—can nearly double the cost of green hydrogen produced via electrolysis.

This highlights a fundamental reality: access to cheap and stable renewable electricity is not a secondary consideration, but the starting point for assessing the economic viability of any green hydrogen project. Factors such as geographic location, the electricity procurement model, and hourly price variability are key elements that must be analyzed from the initial design phase.

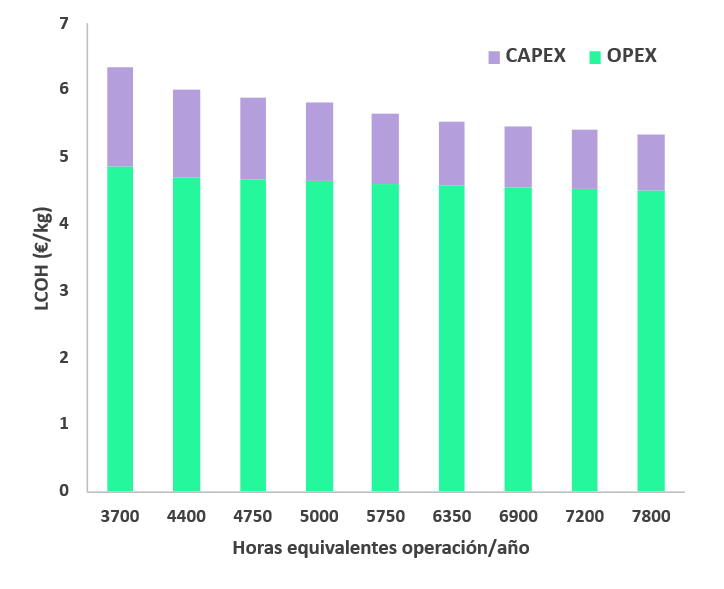

Impact of CAPEX depending on operating hours

While the price of renewable electricity is the main factor in the levelized cost of hydrogen (LCOH), the initial investment (CAPEX) of the electrolysis system becomes more significant when the number of equivalent operating hours decreases.

In such cases, the fixed equipment costs are spread over a smaller annual hydrogen output, which increases the cost per kilogram. Therefore, maximizing the utilization of the electrolyzer is essential to improve the system’s profitability.

Illustration 3. Dilution of CAPEX & OPEX as a function of operating hours

Our analysis shows that when the electrolyzer operates below 5,000 hours per year, the initial investment (CAPEX) can account for more than 35% of the levelized cost of hydrogen (LCOH). In contrast, if more than 7,000 equivalent hours are reached annually, its share drops below 20%. This difference is due to the fact that fixed costs are spread across a higher hydrogen output, improving the economic efficiency of the system. To put this variation into perspective: with a base LCOH of 5 €/kgH₂, that 15% change represents a difference of 0.75 €/kgH₂, which is a significant amount when assessing hydrogen competitiveness.

Thus, it is not enough to install renewable capacity; it is essential that it enables continuous and stable operation of the electrolyzer. The number of equivalent hours is a critical metric in any cost model.

Why is the renewable hourly profile crucial?

To maximize the equivalent operating hours of the electrolyzer, the hourly generation profile of renewable energy must be well aligned with the power demand of the electrolysis system.

When solar or wind energy production does not match the needs of the electrolyzer, production decreases, assets are underutilized, and the Levelized Cost of Hydrogen (LCOH) increases directly. For this reason, an energy system design that is well adapted to the temporal behavior of renewable resources is key to achieving both technical efficiency and economic profitability for the project.

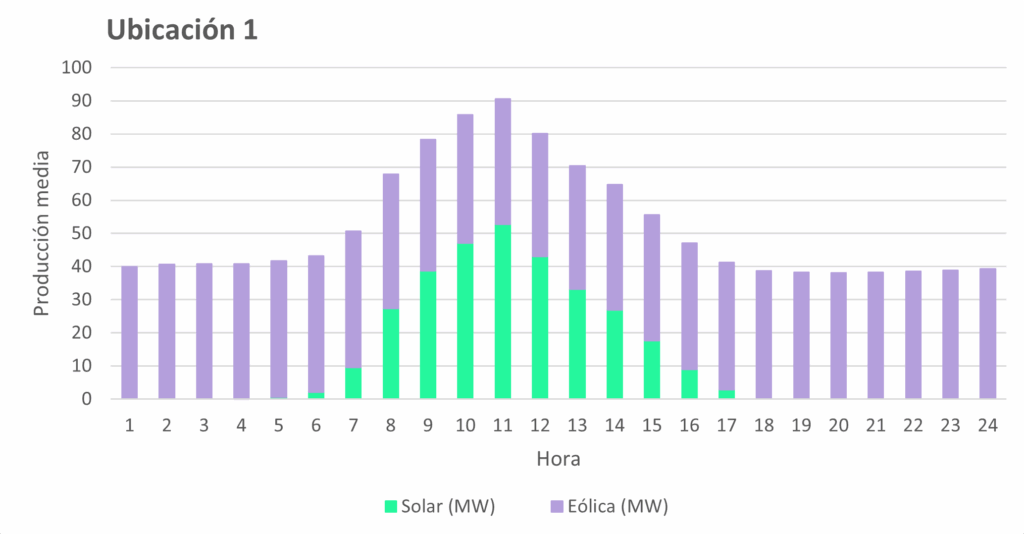

Illustration 4. Complementarity between parks

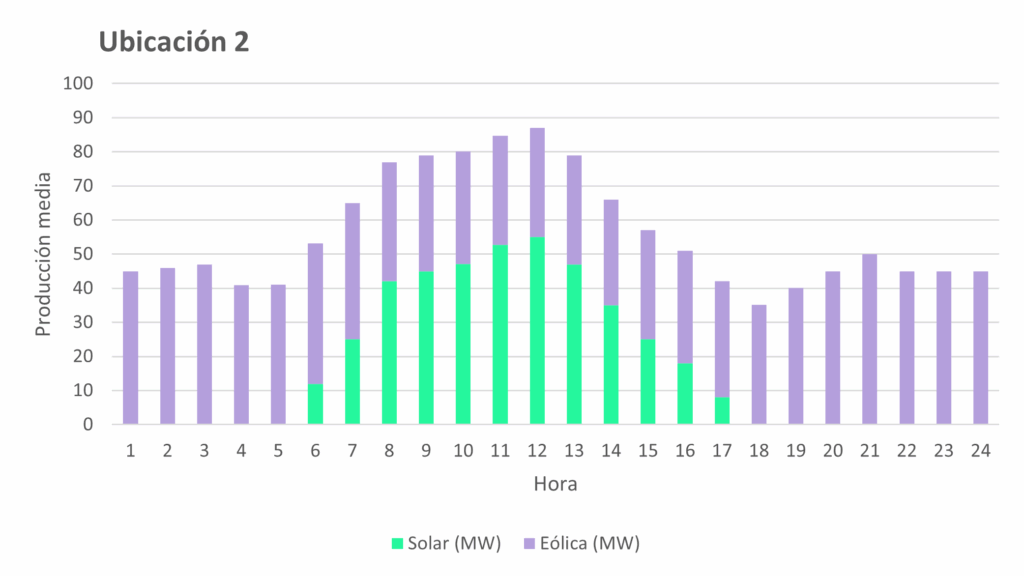

This effect becomes clearly evident when comparing two locations with the same installed renewable capacity but different hourly generation profiles.

Through our techno-economic simulation model, we analyzed the equivalent operating hours of the electrolyzer achieved in each location, which allowed us to precisely quantify the impact of the local renewable resource on the Levelized Cost of Hydrogen (LCOH).

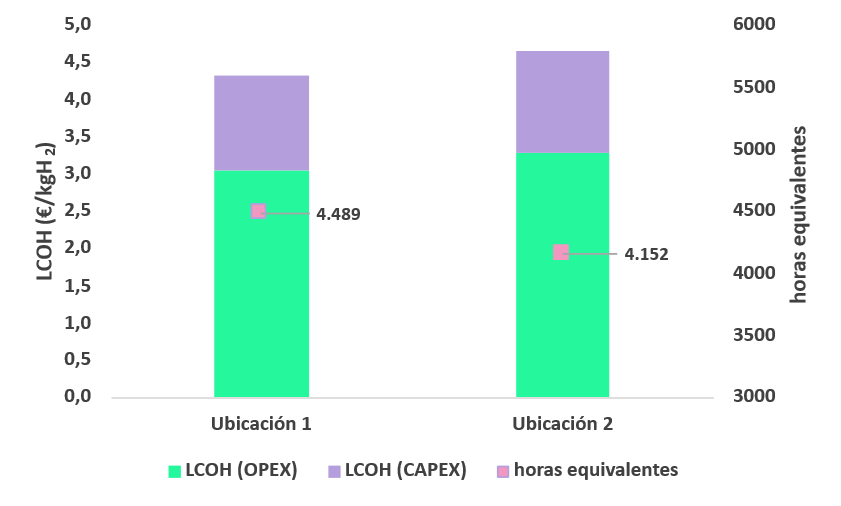

Illustration 5. LCOH for the same project depending on location

Even with the same installed renewable power, a difference of just 500 equivalent hours per year can result in an increase of up to €0.5/kg in the Levelized Cost of Hydrogen (LCOH), solely due to a lower utilization of the system.

This outcome highlights the importance of using real hourly renewable generation profiles in simulation models to accurately assess hydrogen production.

Hourly techno-economic model: key to designing a profitable hydrogen plant

An hourly techno-economic model is more than just a calculation tool: it’s the foundation for the technical and financial design of an efficient green hydrogen plant.

A comprehensive model should enable to:

- Analyze real hourly profiles of solar and wind generation, tailored to each geographic location.

- Simulate different electricity supply schemes: self-consumption, PPA, or hybrid setups.

- Simulate the hour-by-hour operation of the electrolyzer, accounting for its efficiency and auxiliary consumption.

- Estimate the net hydrogen production with hourly outputs.

- Compare locations not only by their renewable resource potential but also by critical technical variables such as environmental conditions, which impact, for example, the electrolyzer’s cooling needs—especially in warm climates.

A good model not only estimates the cost of hydrogen: it serves as a comprehensive tool for energy, economic and operational design, capable of guiding strategic decisions such as the optimal location of the plant, the electricity supply scheme, or the sizing of the electrolysis system.

Do you want to evaluate the LCOH of your green hydrogen project?

At AtlantHy we are experts in modeling hydrogen projects to optimize the LCOH. In fact, we were the advisors to MIBGAS in the creation of the Renewable Hydrogen Price Index in Iberia (IBHYX).

Don’t hesitate to contact us if you want to optimize the LCOH of your hydrogen project!