Renewable hydrogen can be produced through many different pathways; however, water electrolysis is expected to become the primary method due to its capacity to produce the vast quantities of hydrogen that will be required in the coming years. This raises a fundamental question: if we produce this gas from water, will the demand for that water be excessively high? Where exactly is water consumed within a renewable hydrogen and synthetic fuels production plant, and how can we reduce this consumption?

In this AtlantHy Academy article, we’ll uncover the secrets of water consumption in green hydrogen plants.

Introduction and context

Hydrogen is considered a key component in achieving global climate goals, primarily due to its ability to store and transport clean energy. As a fuel that produces only water as a by-product when used, hydrogen has the potential to decarbonise hard-to-electrify sectors such as heavy transport, the chemical industry, high-temperature heat generation and metallurgy.

The International Energy Agency (IEA) has highlighted that hydrogen could meet up to 18% of global energy demand by 2050 (IEA, 2019). However, for this potential to be realised, it is crucial to develop hydrogen production methods that do not rely on fossil fuels—and this is where water comes into play.

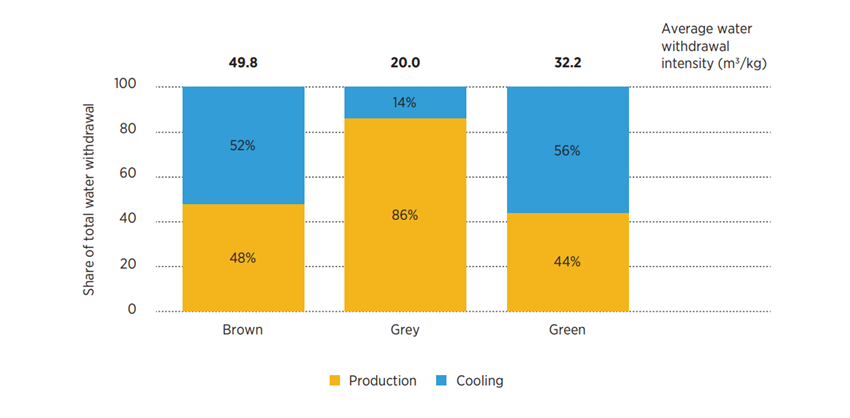

Green hydrogen production requires high-purity water for the electrolysis process, which means that the selected plant location must have access to water resources. Conventional sources include surface freshwater supplies, brackish groundwater, and seawater. Nevertheless, in order to minimise water consumption—and particularly in arid regions—it is likely that recycled water from non-conventional sources, such as treated wastewater and industrial effluents, will be needed (Kimball, 2024). In addition, the hydrogen production process generates substantial amounts of heat that must be dissipated, which is why cooling units are always included. This implies not only greater water consumption, but also increased electricity use and space requirements.

Water in green hydrogen production

Below, we highlight three key points that describe and emphasise the importance of water in hydrogen production:

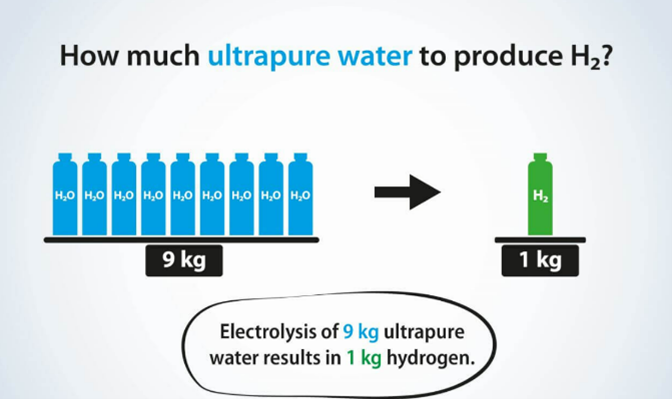

Quantity: producing 1 kg of hydrogen through electrolysis requires approximately 9 litres of water. Given the scale at which hydrogen is expected to be produced in the future, water consumption could become significant—particularly in regions facing water scarcity.

Efficiency and lifespan: similarly, the efficiency of the electrolysis process depends largely on the quality of the water used. To ensure optimal performance and extend the lifespan of the components, it is essential that the water is of high purity—generally equivalent to deionised or distilled water. Impurities such as salts, minerals, and other contaminants can lead to deposit formation on the electrodes, increase electrical resistance, and accelerate membrane degradation in proton exchange membrane (PEM) electrolysers. In addition, the presence of chlorides and other corrosive ions can cause irreversible damage to electrolyser materials (Hans Becker, 2023).

Water treatment: this may include processes such as filtration, reverse osmosis, and deionisation to remove impurities and ensure the quality required for efficient and sustainable electrolysis (Hans Becker, 2023). The use of freshwater in hydrogen production presents challenges, particularly in water-scarce regions. To mitigate these impacts, alternative water sources—such as desalinated seawater—are being explored (Kimball, 2024).

Other possibilities

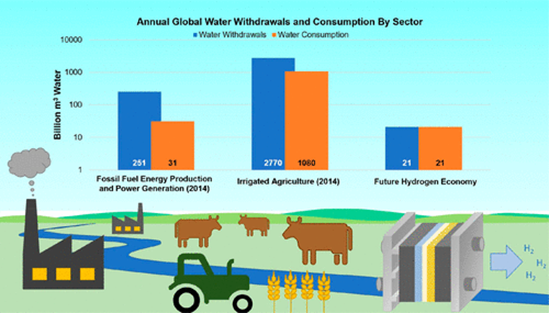

From the AtlantHy team, we find it relevant to highlight that hydrogen production via electrolysis consumes only a minimal amount of water when compared to other sectors—such as irrigated agriculture, which accounts for 70% of total global freshwater withdrawals, equivalent to over 2,700 billion m³ annually. Of this total, approximately 1,100 billion m³ of water are consumed each year—more than 50 times the amount that would be required in a future hydrogen economy (Rebecca R. Beswick, 2021).

Nevertheless, although adjacent sectors use far more water than even the most ambitious projections for hydrogen production, concerns over freshwater scarcity highlight the need to reduce water withdrawals across all possible domains. Therefore, proposing a solution that enables hydrogen production to make use of the planet’s abundant saltwater resources could further reduce hydrogen’s water footprint.

To address the water demand in hydrogen production, various alternatives are being explored that can minimise the impact on conventional water resources.

Brine disposal: desalination technology has advanced significantly, and its integration with electrolysis plants can offer a sustainable solution. Recent studies have shown that desalination, when combined with hydrogen production, can be both efficient and economically viable—though it does involve increased energy costs. Any water treatment plant designed to remove salts in order to produce high-purity water will generate a stream of concentrated brine that requires disposal. The location of the facility in an area offering cost-effective brine disposal options will be a key factor in the overall treatment cost, as it involves higher energy expenditure (Kimball, 2024).

Tertiary effluents: unused tertiary effluents have significant potential for large-scale green hydrogen production, requiring lower investment compared to desalinated water and offering greater water supply security than rainwater. In an efficient circular economy, using recycled effluents for green hydrogen production appears more sensible than building additional desalination plants solely for this purpose. Tertiary effluents, with minimal additional purification—mainly to ensure chlorine levels remain below 0.1 ppm at all times—are highly suitable for electrolysis (Phil Woods, 2022).

In summary

It becomes clear that water quality is a critical factor in hydrogen production via electrolysis. Impurities can negatively affect the efficiency, performance, and durability of electrolysers. Although some studies have been conducted, further research is still needed to fully understand these impacts and to develop solutions that enable the use of less pure water sources without compromising performance. Progress in this area is essential for the expansion of green hydrogen as a sustainable energy solution.

The use of salt water, treated through desalination technologies, and recycled tertiary effluents from wastewater treatment plants emerges as a viable and sustainable alternative. These approaches not only reduce competition for freshwater resources but also efficiently incorporate the concept of a circular economy, minimising the need to build additional desalination plants solely for hydrogen production.

With these strategies, along with the development of appropriate policies and regulations, green hydrogen production can be both economically and environmentally sustainable —without increasing water stress and while promoting optimal use of available resources.

We recommend listening to Episode 75 of our podcast: Water Treatment with Sergio Meana (Hidritec) to complement this information with insights from a water treatment expert.

Don’t forget that at AtlantHy, we work daily on projects where the plant’s water consumption can multiply significantly depending on the design choices made.

Don’t hesitate to contact us to get your renewable hydrogen project off the ground!

If you enjoyed this article, stay tuned to keep learning in the second part, where we’ll discuss where the main sources of water consumption lie within a synthetic fuels production plant, as well as highlight strategies for reducing that consumption… Follow us on AtlantHy Academy!

References

Bluerisk, I. a. (2023). Water for hydrogen production. Abu Dhabi.

Hans Becker, J. M. (2023). Impact of impurities on water electrolysis: a review. Sustainable Energy & Fuels, 1-66.

IEA. (2019). The future of hydrogen Seizing today’s opportunities . IEA.

Kimball, B. (18 de Marzo de 2024). Water’s Role in Producing Sustainable Green Hydrogen Power. retrieved from WSP: https://www.wsp.com/en-us/insights/2024-green-hydrogen-power#:~:text=Green%20hydrogen%2C%20also%20known%20as,gases%20%E2%80%93%20pure%20oxygen%20and%20hydrogen.

Madsen, H. T. (27 de Octubre de 2022). Water treatment for green hydrogen: what you need to know. Retrieved from Hydrogen Tech: https://hydrogentechworld.com/water-treatment-for-green-hydrogen-what-you-need-to-know

Phil Woods, H. B.-Z. (2022). The hydrogen economy – Where is the water? Energy Nexus.

Rebecca R. Beswick, A. M. (2021). Does the Green Hydrogen Economy Have a Water Problem? ACS ENERGY LETTERS.