The need for compression

Compressors are devices designed to increase pressure—in this case, of gaseous hydrogen—so that it can be transferred and used. They have been used in industrial settings for more than 100 years.

Characteristics and operation

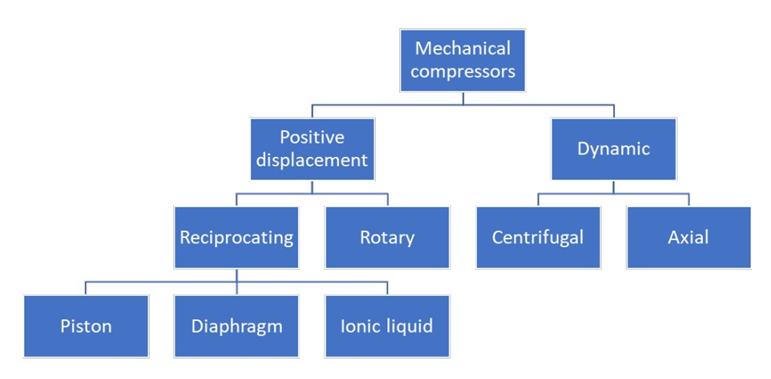

Hydrogen compressors operate using various technologies: pistons, diaphragms, screws, and turbo compressors. Below, we describe how each type functions, focusing specifically on those of a mechanical nature.

Mechanical compressors: these are the most widely used compressors today and are based on the direct conversion of mechanical energy into gas pressure. The most common type is the positive displacement compressor, which operates by reducing the volume in which the gas is confined using a piston. This reduction increases particle collisions and, consequently, the gas pressure (Sdanghi, 2019).

Figure 1. Types of mechanical compressors schematised based on how gas compression is performed (Don, W.G., 2008)

Positive displacement

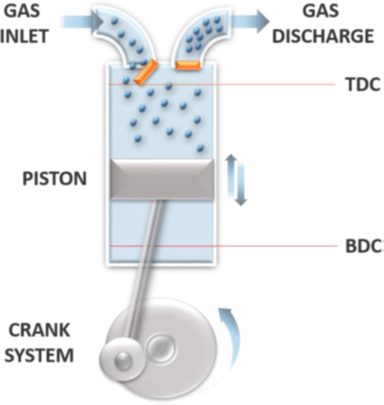

Reciprocating piston compressors: these consist of a piston–cylinder system equipped with two automatic valves—one for intake and the other for discharge. The piston is connected to a crankshaft via a connecting rod, allowing the rotary motion to be converted into linear motion. This compression process requires energy, which is typically supplied by an electric or thermal machine. The upward movement of the piston creates a vacuum in the lower part of the cylinder, causing the intake valve to open and allowing gas to enter. The next stage, known as the suction phase, occurs as the piston moves downward until the intake valve closes.

Illustration 1. Operating diagram of a reciprocating piston compressor (Sdanghi, 2019).

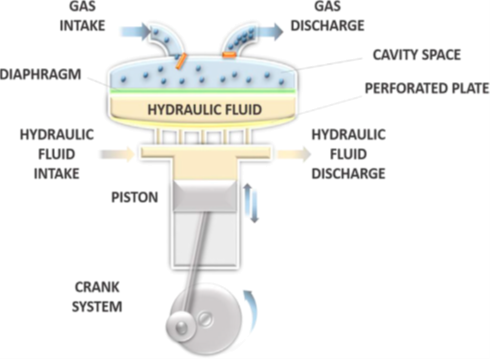

Diaphragm compressors: these offer high efficiency with low energy consumption and minimal cooling requirements (Ahmed S, 2017). Compression is achieved through the movement of the diaphragm, which increases the gas pressure by reducing the volume of the cavity in which the gas is contained.

Illustration 2. Operating diagram of a diaphragm compressor (Sdanghi, 2019).

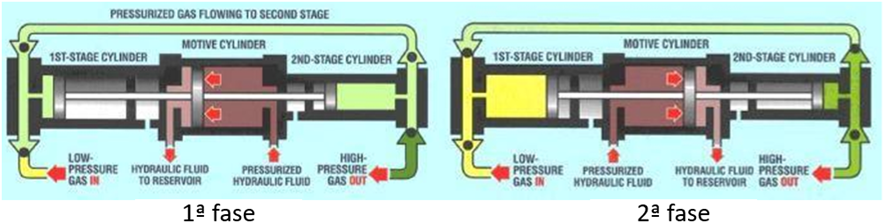

Hydraulic compressors: these are a type of compressor with high efficiency and thermal dissipation, capable of achieving high pressures. They use a hydraulic fluid (typically oil) to compress the gas; as the fluid is driven by a pump, it exerts force on the piston, causing it to move.

Illustration 3. Operating diagram of hydraulic compressors (HydroPac).

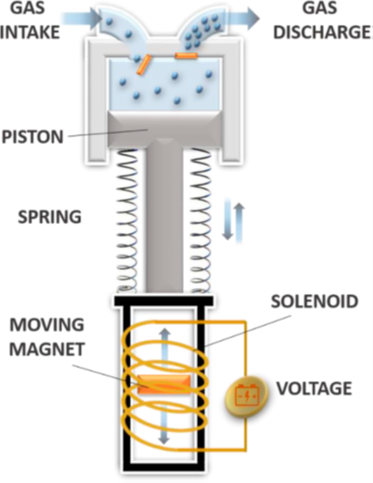

Linear compressors: one of their advantages is that the piston and cylinder are separated by a gas bearing system. Their operation involves compressing a defined portion of gas by applying force with a piston, while another portion of the gas acts as a cushion to prevent friction. They are commonly used in cryogenic applications and, unlike the previously mentioned reciprocating compressors, the piston is directly connected to a linear motor coupled with a resonant spring system. Due to their simple design with few components, they offer reduced costs (Broerman EL, 2015).

Illustration 4. Operating diagram of a linear compressor.

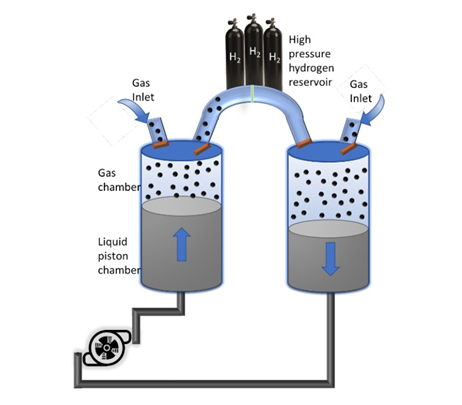

Ionic liquid compressors: before discussing the compressor itself—what are ionic liquids? In short, ionic liquids are salts with low melting points, which means they remain in a liquid state at room temperature. Due to the very low solubility of hydrogen in these salts, high volumetric and energy efficiencies, as well as high compression ratios, can be achieved. In the context of compressors, these liquids replace the solid piston found in positive displacement devices, resulting in improved performance.

Illustration 5. Operating diagram of an ionic liquid compressor.

Rotary compressors

Centrifugal compressors: these are characterised by their isothermal efficiency and allow operation with high flow capacity and a moderate compression ratio. In this case, a rotating impeller compresses the hydrogen as it spins, generating a high-velocity hydrogen flow that is converted into pressure through a diffuser.

Illustration 6. Centrifugal compressor (Kaishan, 2023).

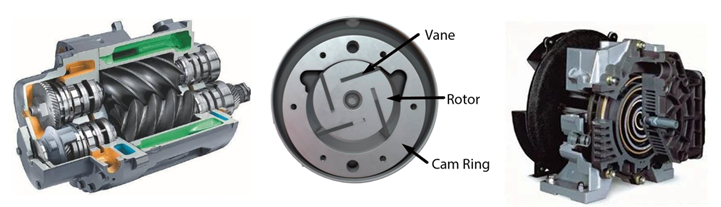

Rotary compressors: known for their high efficiency, compact design, and high noise levels, these operate by trapping gas in a volume which is then reduced, resulting in compression as the rotors turn. This category includes: rotary screw compressors, rotary vane compressors, and scroll compressors.

Illustration 7. Screw compressors (Atlas Copco, 2023), vane compressors (SAVREE), and scroll compressors (IndiaMart).

Lastly…

The compression of hydrogen is an essential part of its storage and transport, enabling the full benefits of the molecule to be realised. Selecting the appropriate compressor depends on a range of factors and requires careful consideration of the specific case within a broad spectrum of available options.

We recommend listening to Episode 58 of our podcast: Hydrogen Compressors with Javier Cuevas (Burckhardt Compression) to complement this information.

We’ll see you in part two, where we’ll be talking about non-mechanical compressors!

References

Sdanghi, G. (2019). Review of the current technologies and performances of hydrogen compression for stationary and automotive applications. Renewable and Sustainable Energy Reviews.

Green, Don W., Perry, Robert H.. (2008). Perry’s Chemical Engineers’ Handbook : eighth edition (Ed. 8th). New York: McGraw Hill.

Ahmed S, S. E. (2017). Hydrogen Compression, Storage and Dispensing Cost. Washington: U.S. Department of Energy.

Broerman EL, B. J. (2015). Hydrogen Compression Application of the Linear Motor Reciprocating Compressor. DOE Hydrogen and Fuel Cells Program.

HydroPac. (s.f.). High Pressure Hydrogen Compressors. Obtenido de http://hydratechcorp.com.my/wp-content/uploads/2015/08/High_Pressure_Hydrogen_Compressors.pdf

Atlas Copco. (2023). Compresor de tornillo, ¿Cómo funciona? Obtenido de https://www.atlascopco.com/es-es/compressors/air-compressor-blog/compresor-de-tornillo-como-funciona.

SAVREE. (s.f.). Rotary Vane Pump. Obtenido de https://savree.com/en/encyclopedia/rotary-vane-pump

IndiaMart. (s.f.). Scroll Compressor. Obtenido de https://www.indiamart.com/proddetail/scroll-compressor-11521392573.html

Kaishan . (2023). CENTRIFUGAL AIR COMPRESSORS. Obtenido de https://kaishanusa.com/centrifugal-air-compressors/